The crash sled test facility essentially consists of two rails on which different carriages (sleds) can roll. These carriages are accelerated by up to ten rubber ropes (high-performance bungee ropes) over a distance of approx. 10 m. In the impact area, the carriage can be braked in a targeted manner by a multi-layer and multi-stage bending plate brake, or it is possible to place a test body in the impact area, which is generally irreversibly deformed during the experiment.

Test Rig Data

- Sled weigth (aluminum and steel slide): 120 kg – 900 kg

- Impact energy: up to 150 kJ

- Impact velocity: up to 20 m/s

- Impact area: up to 6m3

- Measurement technology: Two high-speed cameras, laser-based distance measurement, acceleration sensors up to 1000 g

Applications/Projects

Tyre-Soil-Interaction

Interaction of tyres with deformable soils (here: sand): In this special test setup, the interaction of a tyre with a non-cohesive soil (sand) was investigated. This type of interaction comes into play, for example, when a vehicle skids and slides sideways into the shoulder. The picture shows a tire with the sled behind it (view against the direction of travel).

Spot welds

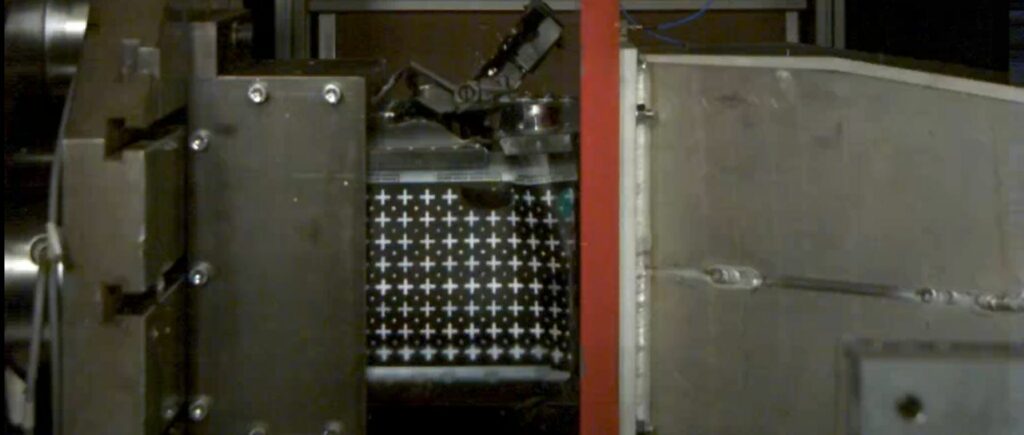

In several test series, spot welds were investigated with regard to their strength with the help of a small aluminum sled (low energy). A special profile was chosen in order to investigate the welding points with respect to both head pull and shear loads. The picture on the left shows exemplary results from a high-speed video.

Batteries

Investigation of the behaviour of batteries in a crash-like load for the creation of crash battery models.

Letzte Änderung: 23. March 2021