The Pop-Up Circular Hub (PUCH) exhibition took place from November 20 to December 8, 2023, in the JUPITER building, a former sporting goods retail store in the heart of Hamburg. The event was a collaboration between the Hamburg Institute for Innovation, Climate Protection and Circular Economy (HiiCCE), BUKEA, Fab City Hamburg and The New Production Institute with the aim to create a temporary hub for circular economy actors in and around Hamburg.

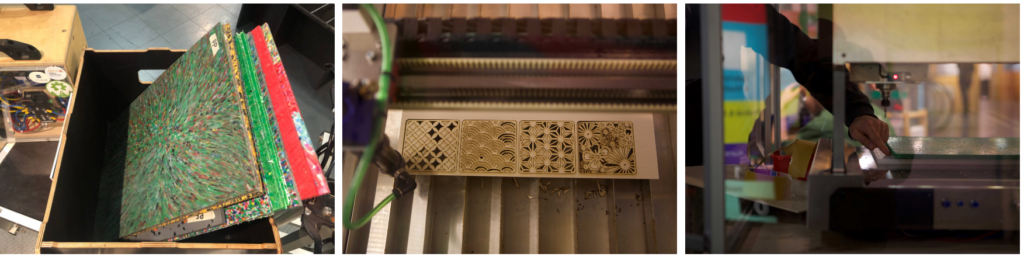

The New Production Institute therefore deployed a pop-up microfactory (so called OpenLab Microfactory), spanning approximately 25m² on the 4th floor with an exhibition space next to it. The microfactory space was equipped with different types of digital manufacturing machines like the Small Lasercutter, CNC-Mill and 3D Printer of the OpenLab Starter Kit (OLSK) as well as different hand tools. The focus beside the machine setup was on sustainability and resource monitoring with a developed open-source energy monitoring system.

⫸ The local network of actors for the microfactory deployment and operation included InMachines Ingrassia GmbH as machine supplier (original equipment manufacturer (OEM)), Insel e.V. with its OpenLab Circular Plastics as service manufacturer for recycled plastic sheets, and Fab City Hamburg e.V. with activities in hands-on workshops, knowledge transfer and engaging the local community.

Setting up a microfactory

The planning phase involved considerations for space and energy consumption limits, emission thresholds, and time scheduling with other organizations sharing the space.

Material procurement involved sourcing electronic components for a modular lamp (published as open-source hardware) and obtaining plastic sheets from Insel e.V. for the Parameo picture frame. Diverse materials for ad-hoc manufacturing included 3D printing filament, cartonage, and wood sheets.

The deployment process encompassed logistics, transport of equipment, installation, calibration, and testing of machines, along with the configuration of the data platform.

The microfactory operation was visible on a dashboard showing the live energy consumption of the machines:

Other operation activities included direct exchange with visitors, performing hands-on workshops like 3D printing intro or building a 3D printer in 2 days. Prototyping included designing cards for one of the art galleries in the building, as well as key rings for Ghana, while production focused on modular mini lamps, Christmas souvenirs, milling precious plastic plates for a solarbox, and Parameo picture frames. CAD/CAM technology played a crucial role in creating and processing designs for machines, including 3D printers and laser cutters.

The development of the data platform and IoT stack aimed at modularizing Node-Red and Grafana Dashboard for easy integration of new machine types and tracking manufacturing process parameters such as energy and material consumption.

Three weeks of local production

Visitor statistics revealed approximately 330 people over three weeks visited the space, with various feedback from people wanted to manufacture their own invations to suggestions for a more visual and less textual content for easier understading.

Manufacturing statistics included the production of 30 modular lamps, aorund 60 Christmas decorations/gifts, repair of a powerbank using 3D printers, 3 laser-engraved cards, 1 laser-engraved and cutted custom post box, milled boxes from recycled plastic sheets for a solarbox, and two Parameo milled picture frames.

Overall, the exhibition showcased a successful integration of sustainability practices, innovative designs, and community engagement in a circular microfactory setting.

Funding

The OpenLab Microfactory is funded in the framework of the dtec.bw research project Fab City at Helmut Schmidt University (HSU/UniBw H) – dtec.bw is financed by the European Union – NextGenerationEU.

Follow us for more at

- Instagram: @openlab_hamburg, @fabcityhh

- LinkedIn: New Production Institute, Fab City Hamburg e.V.