Development of a Metal Hydride-Based Hydrogen Storage Tank Optimized for Aluminum Extrusion Manufacturing for Large Scale Production

In the mobility sector, battery electric vehicles will dominate the future market, especially in private vehicles. Therefore, the use of hydrogen stored in metal hydride (MH) tanks as a potential energy source in mobility is aimed more at heavy commercial vehicles.

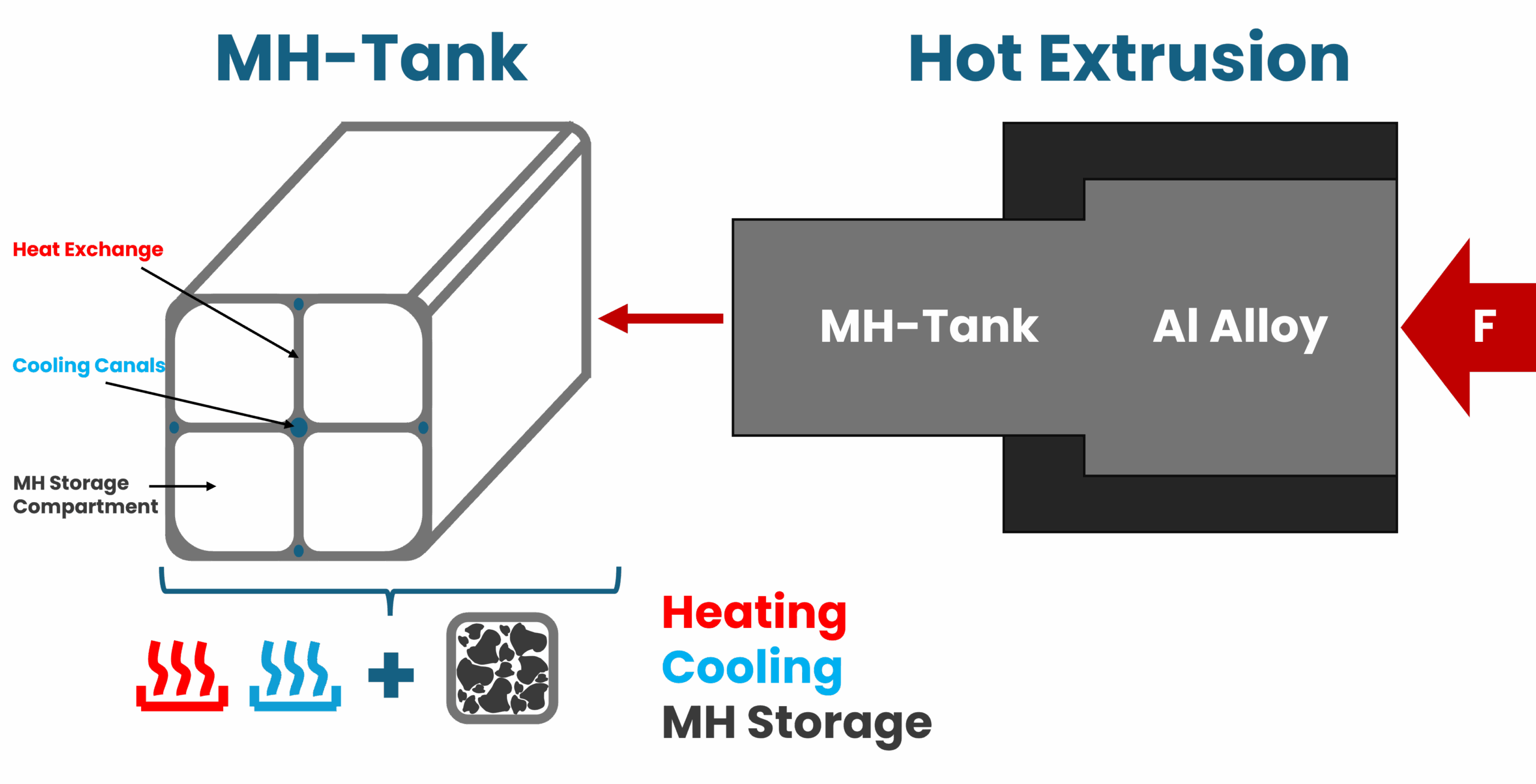

MH storage tanks utilize excess heat from fuel cells for the desorption reaction and must be cooled during absorption (recharging). Thus, cooling channels are a necessary design feature of MH storage vessels. In state-of-the-art MH tanks cooling pipes are used to ensure proper heat management. Those pipes are separate parts and therefore must be assembled into the latter MH tanks.

This work investigates the possibility of manufacturing a hydrogen storage system based on metal hydrides with the process of aluminum extrusion. The focus lies on development and optimization of a tank with its inner and outer geometrical design suiting the properties of large-scale production and the specific characteristics of metal hydrides as hydrogen storage material. The goal is to integrate heat management structures into the general MH tank design to lower production costs and increase the storage capacity while utilizing a manufacturing process well developed in industry.

Material testing and heat management are the main issues of interest in this work. Microstructural analyses and material strength tests are part of the investigations to evaluate the use of aluminum alloys and the manufacturing process as a feasible option for MH storage tank development.

Contact:

Letzte Änderung: 23. October 2025