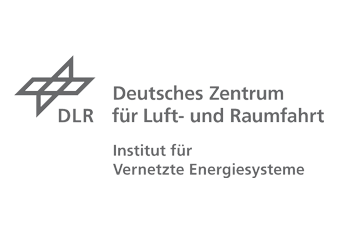

Digital hydrogen process chain for energy transition (Digi-HyPro)

In addition to low-cost production and, if necessary, transport, hydrogen storage in a safe and long-term stable way plays a key role in balancing significant fluctuations between energy production from sustainable sources and demand. The continuous supply of energy must also be ensured to be reliable to bridge longer dark periods without relying on fossil energy sources. Last but not least, energy storage also contributes to the energy sovereignty of Germany and Europe. Energy flows must be controlled to optimally coordinate the dynamics of the grids and storage facilities and thus guarantee the energy supply for electricity and heat.

In the Digi-HyPro project, a Smart-Energy-Transform-Box (SET-Box) development and testing are performed. Such a system can be employed either in a modular (and thus scalable) fashion or decentralized at different locations. Within the box, hydrogen can be produced by an electrolyzer (interface for power output from the electricity grid) and, after passing through a membrane drying process, can be stored compactly and safely in a metal hydride storage tank or supplied into the natural gas grid (interface for feeding into the gas grid). However, if required, the hydrogen can also be extracted from the storage or the gas grid (interface for extraction from the gas grid). For extraction from the gas grid, efficient polymer-based membranes for the coarse separation of natural gas and hydrogen and, in turn, metal hydrides for fine separation are tested. In addition to the fuel cell, the hydrogen from the storage or the gas grid can also be delivered to other systems at a higher pressure level via metal hydride compressors and used, for example, to refuel vehicles (trucks, cars, ships, etc.) (mobility grid interface). The SET-Box thus enables energy to be transformed flexibly and can efficiently and reliably couple the electricity, gas, and mobility grids in a way that serves the grid.

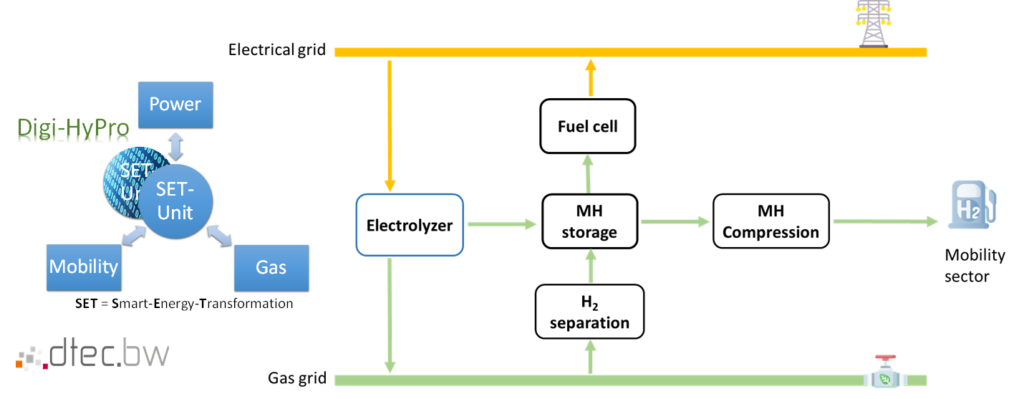

Scope of the SET-box system at laboratory scale (≤ 10 kWel power): The SET-box is under development to integrate and couple the electrolyzer, fuel cell, metal hydride storage, and metal hydride compression. For the integration, system simulations along with experimental coupling have been an integral part of the ongoing work. The simplified diagram shows pictures of the experimental setups on a lab scale. In such a scale the metal hydride-based units, hydrogen and heat management strategies can be further optimized. In a subsequent step, more components will be considered as a part of the set box, such as gas separation units for gas grid coupling.

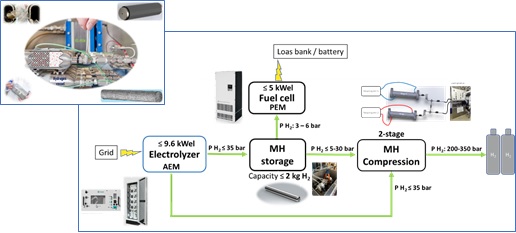

Hydrogen storage: A Prototype metal hydride storage tank has been developed as a proof of concept to investigate further aspects of solid-state hydrogen storage. The prototype has been designed for 15 kg of hydride-forming alloy and to work under mild conditions, i.e. room temperature and low pressures (≤ 35 bar). Such conditions are compatible with the coupling of the metal hydride tank with low-pressure electrolyzers and room-temperature fuel cells. Both the experimental setup and the digital twin are developed in parallel to investigate and optimize one of the most promising hydrogen storage technologies.

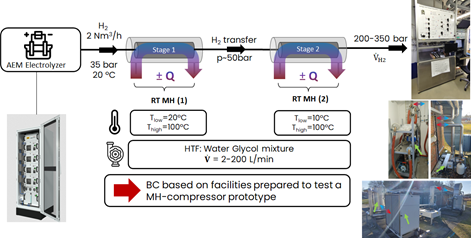

Hydrogen compression: As part of the project,metal hydride compressor prototypes are also under ongoing development. In this case, the first approach has been designed to cover a 2-stage compressor with about 1 kg of hydride-forming alloy in each stage. The second prototype will contain about 20 kg of hydride-forming alloy in each stage. The pressure range of the compressor aims to provide hydrogen with 350 bar for truck refueling.

Duration: 10/2020 – 09/2024

Project partners:

Contact:

Letzte Änderung: 9. February 2023