Trucks continue to play an important role in the transportation of goods and merchandise, as they are primarily used for local transport. However, the energy transition poses a particularly great challenge for this sector, as battery electric systems such as those increasingly seen in passenger cars are not an alternative. The reason for this is that heavy goods vehicles require higher energy densities and long charging times are not economical. Pressurized hydrogen storage systems also do not provide the energy density that is ideally required. An alternative is hydrogen storage in solids, so-called metal hydrides, which store hydrogen in chemical bonds and can therefore achieve particularly high storage densities.

Metal hydride storage systems must meet special requirements. For example, the heat exchange surface in the tank must be optimized so that the heat of reaction for the absorption or desorption of hydrogen can be dissipated or supplied as quickly as possible. Among other things, this is crucial for the time required for loading. Additive manufacturing offers one way of optimizing the tank geometry. Compared to conventional manufacturing, significantly more complex designs can be realized here and the metal hydride storage tank can be further optimized.

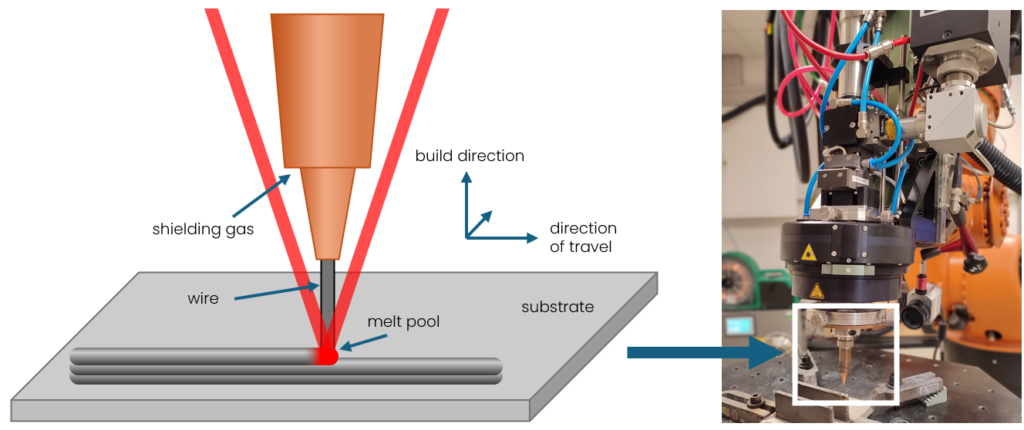

In this project, laser metal deposition welding is used to produce a metal hydride storage tank that optimizes heat transport thanks to its complex internal geometry. To do this, several laser beams generate a molten pool into which a wire is fed. The desired structure is then built up with the help of a robot arm. Compared to powder-based processes, a higher application rate can be achieved using wires and problems with handling the powder can be avoided.

First, various alloys are examined and evaluated with regard to their weldability in the process and the resulting mechanical properties. At the same time, simulation software is used to determine a suitable geometry for the tank. Following these two steps, the metal hydride tank is manufactured and tested.

Contact:

Letzte Änderung: 13. October 2025